Operation concepts and principles

|

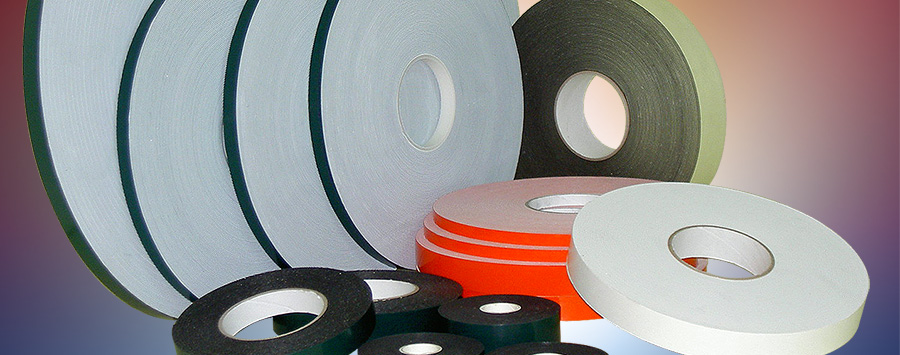

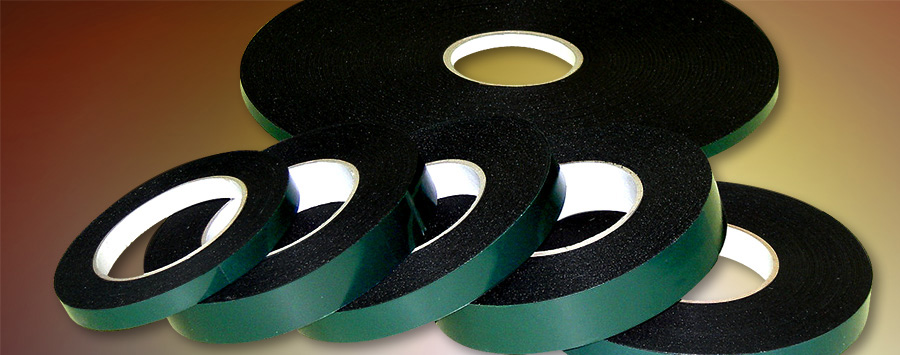

Functions of double coated adhesive tape:

Replacing the traditional processing methods

Increasing production efficiency and product quality.

Traditional gluing methods, such as manual spray brushing, roller coating or filling require specific machines and tools with more skilled operators. Moreover, the drying time is relatively long making the production less efficient. But now, with adhesive tape, you can simply release the paper and conduct lamination and pressure processes, then the consecutive steps can be completed faster. It is easy to operate and upgrades the production efficiency and product quality.

Users’ requirements:

The right choice will let you get something done once for all. The incorrect use of tape will result in more efforts and production costs. Just try it and you will see the superior quality of Swan products.

There is a wide range of brands and types for double coated adhesive tape on the markets. Some renowned brands clearly show the correct applications and the effects of their products. However, most producers only indicate strong adhesion or strong adhesion double-coated adhesive tape. Consequently, the double-coated adhesive tapes for industrial purpose may have an impact on the product quality of packaging materials, shock absorbing materials and plasticized materials (except for stationary application). Therefore, when selecting double sticky tape, the user should understand the correct process and requirements of the laminating material usage.

Insisting on specific production principle:

We specialize in producing special double sticky tapes for industrial applications and employ computerized management for the entire production (using SOP procedures). Besides, materials, formulas and production conditions for each product are all recorded and managed through computer.

Insisting on excellent procurement principle:

We carefully select certified suppliers who offer high quality of products consistently. On the other hand, we always keep sufficient stock and thoroughly conduct material incoming inspection.

Insisting on quality superiority:

Before mass production, a sampling is made for each item to record materials, formulas and production conditions. Then, this information is transferred to the QC department for quality inspection according to the required conditions of each type of tape. Additionally, all production stations are fitted out with quality inspection instructions and standards. At Swan, each individual at the production floor is also an inspector who is responsible for self-controlling quality at each step throughout the entire production processes. In this way, we can instill confidence across customers for using Swan products and also ensure quality consistency.

Customers’ problems are Swan’s problems ~

Customers’ demands are Swan’s requirements ~

Consistent quality is the best salesman ~

SWAN TAPE CO., LTD.

SWAN TAPE CO., LTD.